OUTLINE:

Linear Actuators: Types, Processes, and Design

112

112Linear actuators are important devices used in modern engineering and automation. They are mechanical systems that change energy, usually electrical, hydraulic, or pneumatic, into straight-line motion.

Linear actuators are used in many industries, such as medical equipment, automobiles, industrial automation, and robotics.

Let’s learn how linear actuators work, the different types available, and how to choose the right one.

What is a Linear Actuator?

A linear actuator is a mechanical device that converts rotational motion into linear motion. In simple words, it transforms energy from a motor or other source into a straight-line movement that pushes, pulls, lifts, or tilts objects.

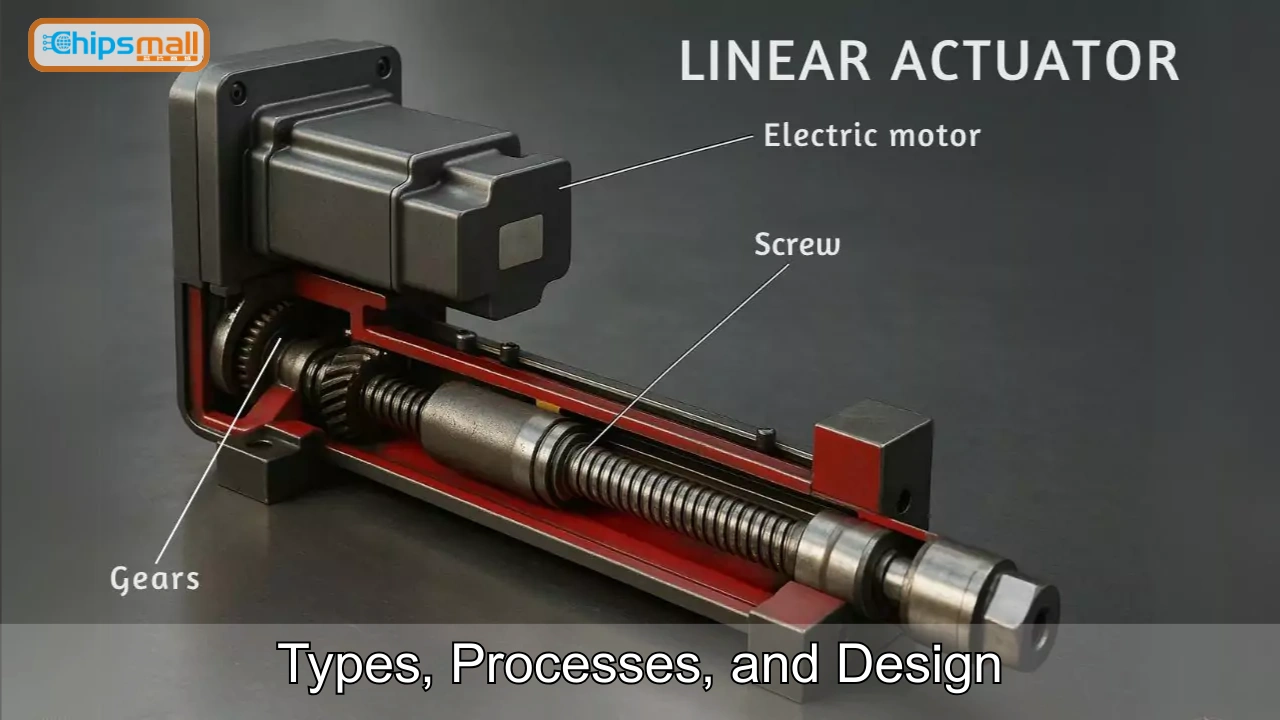

Electric linear actuators typically consist of a motor, a lead screw or ball screw, and a nut. When the motor rotates the screw, the nut moves along the thread, generating linear motion. This principle is based on an inclined plane, where rotational force is converted into movement along a straight path.

Linear actuators are valued for their precision, reliability, and efficiency. They allow automation in environments where manual movement would be slow, inefficient, or impossible.

How Does a Linear Actuator Work?

The way a linear actuator works depends on its type. However, all linear actuators follow one basic idea. They convert energy into controlled straight-line movement. This movement is used to push, pull, lift, or move objects.

-

Electric Linear Actuator: An electric linear actuator uses an electric motor to create motion. When the motor turns, it rotates a screw inside the actuator. This screw moves a nut forward or backward along the threads, which creates straight-line motion. Electric actuators usually use DC power such as 12V, 24V, 36V, or 48V, though some use AC power. Gears are often added to control speed and increase force. Limit switches are built into stop the actuator automatically when it reaches its maximum extension or retraction. This helps prevent damage.

-

Hydraulic Actuator: A hydraulic actuator works by using pressurized hydraulic fluid. The fluid is pushed into a cylinder, which moves a piston back and forth. This motion creates strong and smooth linear movement. Hydraulic actuators can produce very high forces, making them suitable for heavy loads. They are commonly used in construction machines, industrial presses, and material handling equipment, where strength is more important than speed or precision.

-

Pneumatic Actuator: A pneumatic actuator uses compressed air to move a piston inside a cylinder. When air pressure is applied, the piston moves and creates linear motion. These actuators move very quickly and are ideal for tasks that repeat again and again. Pneumatic actuators are widely used in robotics, factory assembly lines, and automation systems.

-

Mechanical Actuator: A mechanical actuator creates linear motion using simple parts such as cams, levers, or linkages. When these parts rotate or move, they push or pull an object in a straight line. Mechanical actuators have a simple design and are used in low-force applications. Common examples include hand-cranked car jacks and retractable pens.

-

Piezoelectric Actuator: A piezoelectric actuator works by applying an electrical voltage to special ceramic materials. When voltage is applied, the material expands or contracts slightly, creating motion. This type of actuator provides extremely precise movement, even at very tiny scales. Piezoelectric actuators are used in scientific instruments, microscopes, and nano-positioning systems where high accuracy is required.

Types of Linear Actuators

Linear actuators come in different types, and each type is designed for specific tasks. Let’s look at the main types and understand how they are used.

Electric Linear Actuators

Electric linear actuators are the most widely used type because they are easy to control and very precise. They use an electric motor to create straight-line movement.

The motor rotates a screw, which moves a nut forward or backward. This movement creates linear motion. These actuators are quiet, clean, and easy to program, which makes them popular in modern automation systems.

Subtypes:

-

Screw-driven actuators (lead screw, ball screw, roller screw)

-

Belt-driven actuators

-

Gear-driven actuators

Applications:

-

Adjustable hospital beds

-

Robotics

-

Solar tracking systems

-

Standing desks

-

Vehicle seat adjustment

Hydraulic Actuators

Hydraulic actuators are known for their very high force output. They use pressurized liquid to create motion, making them suitable for heavy-duty tasks.

In this type, pressurized fluid is pushed into a cylinder. The fluid moves a piston, which creates straight-line motion. These actuators are strong, durable, and reliable in tough working conditions.

Applications:

-

Excavators

-

Industrial presses

-

Lift gates

-

Aerospace systems

Pneumatic Actuators

Pneumatic actuators use compressed air to produce linear motion. They are fast and work well for repeated movements.

Compressed air enters a cylinder and pushes a piston forward or backward. This creates quick and smooth motion. Pneumatic actuators are often used where speed and safety are important.

Applications:

-

Factory assembly lines

-

Robotics

-

Packaging machines

-

Textile machinery

Mechanical Actuators

Mechanical actuators use simple mechanical parts to create linear motion. They are easy to understand and maintain.

These actuators work using mechanisms such as screws, gears, or belts. They are best suited for low-force tasks and manual systems.

Examples:

-

Ball screw

-

Lead screw

-

Rack and pinion

-

Belt-driven actuators

Applications:

-

Low-force tasks

-

Mechanical presses

-

Manual jacks

Piezoelectric Actuators

Piezoelectric actuators are used when very small and accurate movement is needed. They are not designed for large motion or heavy loads.

They work by applying voltage to special materials that expand or contract slightly. This creates extremely precise movement in very small steps.

Applications:

-

Optical devices

-

Scientific instruments

-

Semiconductor manufacturing

-

Microscopy systems

Other Types of Actuators

Some actuators are designed for special needs and unique applications. Telescoping actuators offer a long stroke length while staying compact, which makes them useful in tight spaces. Voice coil or coiled actuators provide smooth and fast motion without direct contact. Ball slides use ball bearings to reduce friction and improve accuracy. Electro-mechanical actuators combine motors and mechanical systems to offer precise and programmable control.

Applications:

-

Compact automation systems

-

Precision positioning equipment

-

High-speed motion control tasks

Components of a Linear Actuator

Every linear actuator has several key components:

-

Motor: Powers motion (DC or AC, stepper, or servo).

-

Lead/Ball Screw & Nut: Converts rotation into linear movement.

-

Limit Switches or Sensors: Prevent over-travel or collision.

-

Gearbox: Adjusts torque and speed.

-

Controller: Manages position, speed, and force; can integrate with PLCs.

-

Power Supply or Converter: Provides energy in the correct voltage and current.

-

Phase Index or Feedback Sensors: Provide precise position feedback.

Key Parameters for Choosing a Linear Actuator

When selecting a linear actuator, consider the following:

-

Load Capacity: Load capacity tells you how much force the actuator can handle. Dynamic load is the amount of force the actuator can move while it is operating. Static load is the amount of force the actuator can hold when it is not moving. Both values are important to avoid damage or failure.

-

Stroke Length: Stroke length is the total distance the actuator rod moves from fully retracted to fully extended. You must choose an actuator with a stroke length that matches the required travel distance of your application.

-

Speed: Speed refers to how fast the actuator can extend or retract while carrying a load. Higher speeds are useful for quick movements, while slower speeds provide better control and higher force. Speed usually changes depending on the load applied.

-

Duty Cycle: Duty cycle describes how long the actuator can operate before it needs to rest. It is usually shown as a percentage of operating time compared to resting time. A proper duty cycle helps prevent overheating and extends the life of the actuator.

-

Environmental Protection: Environmental protection is important when the actuator works in harsh conditions. IP ratings show how well the actuator is protected from dust, water, and moisture. Higher IP ratings are needed for outdoor or industrial environments.

-

Mounting and Space Constraints: Mounting and space limits affect how the actuator fits into your system. Choosing the correct mounting style, such as fixed, pivot, or pin-to-pin, improves stability and smooth operation. Always check available space before selecting an actuator.

-

Precision: Precision means how accurately the actuator can reach and hold a position. Some applications, like robotics or scientific instruments, need very accurate positioning. In these cases, actuators with sensors or feedback systems are the best choice.

Applications of Linear Actuators

Linear actuators are used in many industries because they provide reliable and controlled straight-line motion. Some common areas where they are widely used are:

-

Industrial Applications: In industrial settings, linear actuators are used to automate machines and processes. They help control movement in robotic arms, open and close conveyor belt gates, position tools in CNC machines, and handle packaging automation. These actuators improve speed, accuracy, and safety in factories.

-

Medical Applications: In the medical field, linear actuators help adjust equipment smoothly and safely. They are commonly used in hospital beds, dental chairs, patient lifts, and ventilator adjustment systems. Their quiet operation and precise control make them ideal for patient care.

-

Automotive Applications: Linear actuators are widely used in vehicles to improve comfort and functionality. They operate power tailgates, move adjustable seats, open and close sunroofs, and control air brake systems. These actuators help make vehicles more convenient and safer to use.

-

Consumer Applications: Many everyday products use linear actuators for comfort and ease of use. Standing desks use them to change height, solar trackers use them to follow the sun, window openers use them for ventilation, and adjustable furniture uses them for smooth movement.

-

Special Applications: Linear actuators are also used in advanced and demanding environments. In space exploration, they operate robotic arms, valves, and locking systems. In robotics, they handle repeated and precise movements in factories and automotive production lines. In snowblowers, linear actuators automatically adjust the chute direction for better control.

Linear Actuator Design Principles

Linear actuator design is based on basic mechanical and electrical ideas. Understanding these principles helps in choosing the right actuator and using it safely and efficiently.

-

Inclined Plane Principle: The inclined plane principle explains how a lead screw works. The screw acts like a ramp wrapped around a shaft. When the motor rotates the screw, torque is changed into linear force, which moves the load forward or backward over a distance.

-

Power Considerations: The power output of a linear actuator depends on the motor’s torque and speed. A stronger motor can produce more force, while a higher speed reduces available force. Actuator datasheets often include graphs that show the relationship between force, speed, and current draw to help with proper selection.

-

Efficiency: Efficiency shows how well the actuator converts input energy into useful motion. High efficiency means less energy is lost. Ball screw actuators usually have higher efficiency than lead screw actuators, which helps reduce power use and heat. Efficiency also affects if holding brakes or power adjustments are needed.

-

Duty Cycle and Life Span: Using the actuator within its rated duty cycle helps prevent overheating and early failure. Avoid side loading, extreme voltage levels, and excessive force to extend the actuator’s life. High-quality actuators can perform hundreds of millions of cycles with little or no maintenance.

-

Environmental Adaptations: Standard linear actuators are designed for indoor and clean environments. For harsh conditions, special actuator designs are available. These include actuators built for wet areas, dusty locations, cold temperatures, and even underwater use.

How to Choose a Linear Actuator

Choosing the right linear actuator is important for safe and smooth operation. The correct choice also improves performance and increases the life of the system.

Here are the key factors you should consider:

-

Load Capacity: Load capacity shows how much force the actuator can handle. Dynamic load is the force that the actuator can move while it is operating. Static load is the force the actuator can hold when it is not moving. Always make sure both values meet your application needs.

-

Stroke Length: Stroke length is the total distance the actuator rod can travel from fully retracted to fully extended. Choose a stroke length that matches the required movement of your system.

-

Speed: Speed tells you how fast the actuator moves while carrying a load. Heavier loads usually reduce speed. Select a speed that balances smooth motion and efficiency.

-

Duty Cycle: Duty cycle is the ratio of operating time to resting time. Following the rated duty cycle helps prevent overheating and protects the motor from damage.

-

Environmental Conditions: The working environment affects actuator choice. Some actuators are built for clean indoor use, while others are designed for dust, moisture, extreme temperatures, or underwater conditions.

-

Mounting Style: Mounting style plays a big role in actuator performance. Options include fixed, pivoting, pin-to-pin, and telescopic mounting. Proper mounting helps avoid side loading and ensures stable movement.

-

Precision Needs: Some applications need very accurate movement, such as robotics or laboratory equipment. Other applications only need simple forward and backward motion. Choose an actuator that matches your accuracy requirements.

-

Energy Source: Linear actuators can use electric power, hydraulic fluid, or compressed air. The best choice depends on available power, required force, and working conditions.

-

Size and Space Constraints: Space limits can affect actuator selection. Compact or telescopic actuators work well in tight spaces where standard actuators cannot fit.

-

Safety Features: Safety features help protect both equipment and users. Limit switches, sensors, and overload protection prevent overextension, damage, and unsafe operation.

Benefits of Linear Actuators

-

Precision and Control: High accuracy in positioning and repeatable motion.

-

Safety: Safer than some manual or hydraulic systems.

-

Durability: Many actuators perform millions of cycles with minimal maintenance.

-

Quiet Operation: Most operate below 55 dB.

-

Easy Installation: Compact design allows quick setup with minimal wiring.

-

Cost-Effective: Initial cost may be high, but long-term benefits outweigh alternatives.

-

Versatility: Suitable for a wide range of industries and applications.

Common Mistakes to Avoid When Using Linear Actuators

-

Overloading: Exceeding dynamic or static load limits can damage the actuator.

-

Ignoring Duty Cycle: Continuous operation without rest can overheat motors.

-

Side Loading: Forces applied at an angle can reduce efficiency and lifespan.

-

Improper Mounting: Incorrect alignment causes wear and binding.

-

Environmental Neglect: Dust, moisture, and extreme temperatures can shorten life if not considered.

Conclusion

Linear actuators are useful devices that turn motor movement into smooth and controlled straight-line motion. Even though they are built on simple mechanical ideas, they play a major role in modern automation and machine control.

The right actuator choice depends on factors such as load, travel distance, speed, duty cycle, accuracy, and working environment. When these factors are matched correctly, linear actuators work safely, last longer, and need very little maintenance.

From adjusting hospital beds to moving solar panels and guiding robotic arms, linear actuators help machines move with accuracy and reliability. They continue to support smarter designs and better performance in many industries around the world.

FAQs

Q1: Can a linear actuator lift heavy objects?

Ans: Yes, depending on its load capacity. Hydraulic actuators are best for very heavy loads.

Q2: Are linear actuators noisy?

Ans: Most electric actuators are quiet, while hydraulic ones may make more noise.

Q3: Can a linear actuator work outdoors?

Ans: Yes, if it has the right environmental protection, like an IP-rated casing for dust or water.

Q4: Do all actuators need electricity?

Ans: No, some use compressed air (pneumatic) or hydraulic fluid instead of electricity.

Q5: How precise can a linear actuator be?

Ans: Piezoelectric actuators can move very precisely, even at the nanometer level.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: